Project Description

Calcium Silicate insulation is recommended for use in the petrochemical, power generation and process industries where piping and equipment operate at tempeatures up to 1,200°F.

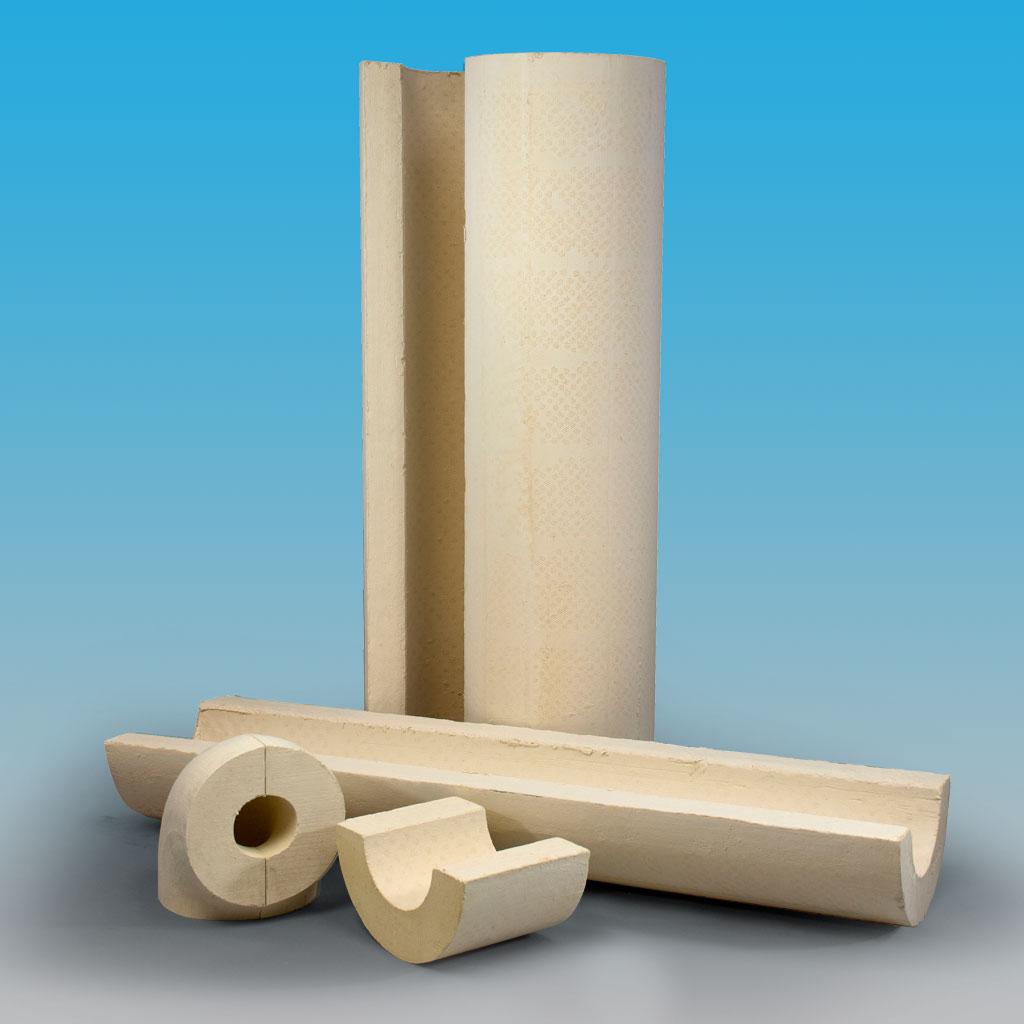

Calcium Silicate Insulation

Calcium Silicate insulation is the choice for high-temperature pipe and equipment due to its high strength and durability, low thermal conductivity and corrosion inhibiting performance.

TPSX-12™ Calcium Silicate Insulation

TPSX-12 is a filter pressed, high-temperature, water-resistant calcium silicate insulation manufactured and sold through our nationwide network of distribution partners. Third-party verified to meet or exceed all physical property requirements of ASTM C533 Type I.

Calcium Silicate insulation is engineered to protect industrial piping and equipment operating continuously at temperatures up to 1200℉ (650℃). Contains integral inorganic silicate chemistry to inhibit corrosion under insulation (CUI). The filter pressing process provides on average twice as much compressive strength vs. the ASTM minimum requirement and is much stronger than North American molded calsil. TPSX-12 is calsil, only better.

Benefits

- Meets/Exceeds ASTM C533 Type I

- Filter Pressed Calsil is:

– Lighter

– Stronger

– More Water-Resistant

– Available in more sizes

Fitting Types

- 90º Elbows

- 45º Elbows

- Tees

- Pipe Covering

- Segmented